Peck Drilling Stone, Glass, and Ceramic with the Gunther Diamond Drill System

We use the peck drilling method to get the best results with the Gunther Diamond Drilling System. In this article, we'll explain how to peck drill using Gunther Diamond Drilling Systems to maximize speed, precision, and consistency.

What is Peck Drilling?

Peck drilling involves a series of short, intermittent drilling actions rather than one continuous motion. Briefly pausing the drill bit helps clear the debris that is created from the drilling action.

If we do not remove the debris, it remains in the hole and is ground into a muddy slurry that can clog your drill bit. If your drill bit gets clogged, the water stops and then your drill bit and the hole can over heat.

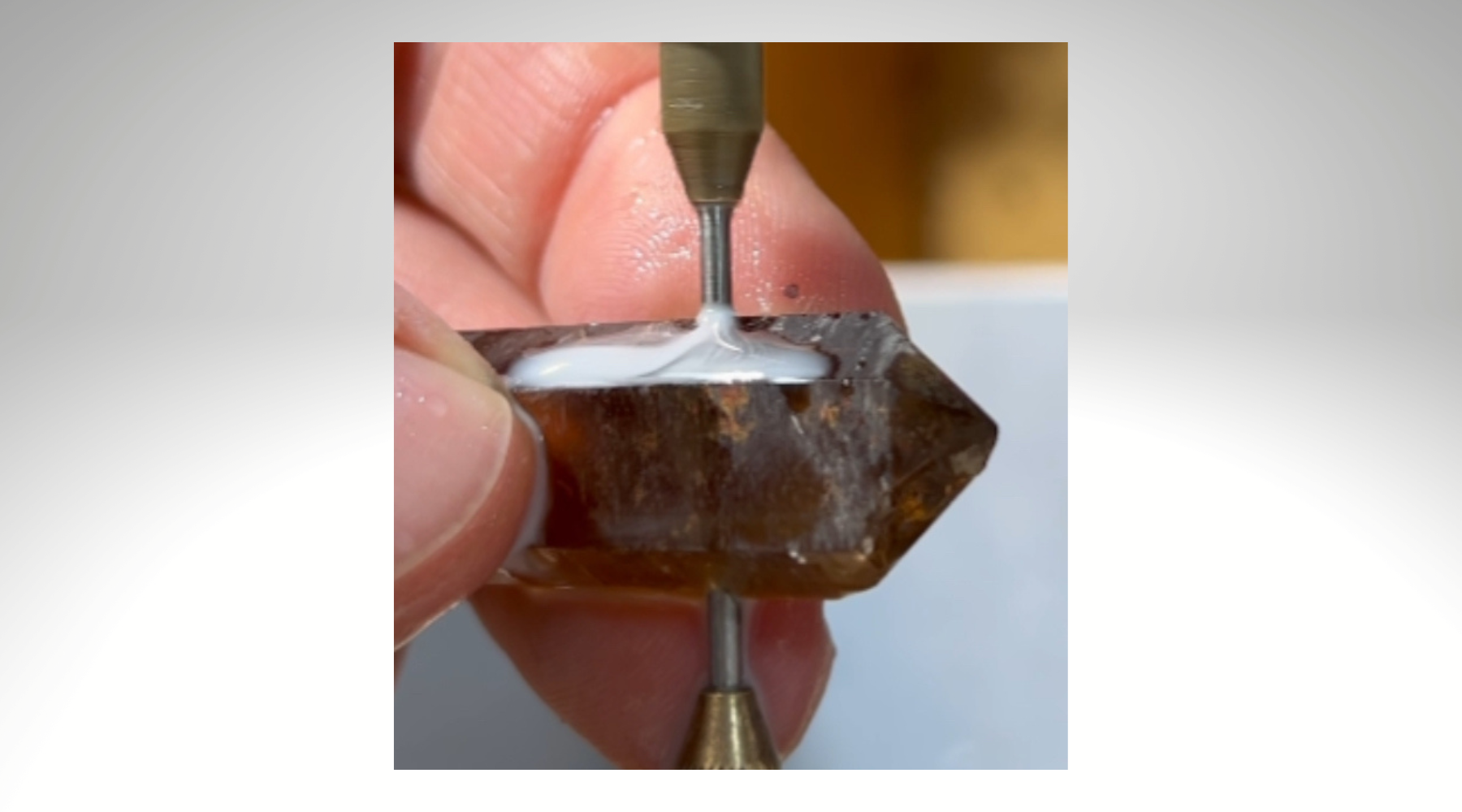

Using pressurized water to clean the hole quickly removes debris and keeps the drill bit and material at a safe temperature.

The use of pressurized water and drill pecking is essential for clean, consistent stone, glass, and ceramic drilling.

Here are general peck cycle examples we use for drilling different materials and situations, but remember that every situation is unique, and you can adjust these to fit your needs.

Hard Materials With a 2.5mm Drill Bit

When drilling a hard stone, glass, or ceramic with a 2.5mm drill bit, the cycle should be approximately 4 seconds of drilling and then a pause.

During the pause, reduce the pressure on the quill lever. Reduce it just enough to allow water to boil out of the hole. It should not be a full retraction of the quill, but rather just enough to flush the hole.

Avoid taking the drill bit in and out of the hole when possible - you might nick the edge of the hole and cause damage.

If you are using a TBH Pro 3 system and need to clear the drill bit then proceed with a full retraction of the quill to clear the drill bit, but be careful when going back into the hole.

When this water flows out, it should flush the debris from the hole. Once the water is clear, you can apply pressure to the quill lever and start a new cycle.

Summary

- 4 Second Drill Action

- 1 – 2 seconds pause and release the pressure on the quill to allow water to flow out of the hole.

Soft Materials With a 2.5mm Drill Bit

Gunther Diamond Drilling Systems prefer to drill hard materials like quarts, agates, and glass instead of soft materials like soapstone or chalky turquoise. Hard materials typically form a solid core inside the drill bit. The drill bit ejector needle clears the drill bit better when creating a solid core.

Soft stones typically don't form a core. Instead, the material inside the drill bit grinds up to create excess debris that needs to be ejected. When we don't flush this debris, it clogs the drill bit, and the water stops flowing. When the water stops, the drill bit can overheat quickly and damage your drill bits.

To mitigate this, we increase the water pressure and shorten the drilling cycle for a faster pause rate. This will allow more water to flow and flush the excess debris from the hole. Or material you are drilling.

Summary

- Increase the water pressure

- 2 Second Drill Action

- 1 – 2 Second pause and release the pressure on the quill to allow water to flow out of the hole.

Technique Changes Of Drill Bit Size

Drill Bits Smaller Than 2.5mm

Drill bits smaller than 2.5mm will tend to clog more easily. The area inside the drill bit is smaller, and the debris tends to pack around the ejector needle and stop the water feed.

To manage this, we use a shorter, faster peck drilling cycle so there are more pauses, and the hole can be flushed more frequently. Additionally, we will increase the water pressure to help keep the drill bit clear and have more water flushing away debris.

Drill Bits From 2.5mm to 5.0mm

Drill bits with 2.5mm and 5.0mm diameters are the easiest to use with all three Gunther Drilling Systems (i.e., TBH Pro 3, The Hobby, Multidrill Water Swivel Adapter Kit). These diameters can handle longer Peck Drilling Cycles for faster drilling. When we use these diameters, you can vary the cycle for preference and material type.

When drilling holes in hard materials in the 4.0mm to 5.0mm diameter, you might create a strong core inside the drill bit that can bind and damage the bit or material. This binding becomes a more significant issue on larger drill bit diameters, but the 4.0mm to 5.0mm is possible on harder stones. Make sure the material you are drilling is held flat while drilling. Change to a Flat Rest Insert for the Magnetic Base if needed.

Drill Bit From 5.0mm to 8.0mm

Large-diameter drill bits have challenges like small ones, but the challenges are different. Clogging is not typically a concern with larger-sized bits, but the bits can break if they are not used with good technique. When you drill a stone with a large diameter drill bit, you will create a more prominent core of material that can be strong and can create a binding effect on the drill bit. We have found that this binding can grab and break the drill bit if you are not careful.

We keep the material we are drilling flat and stable to prevent binding damage to the bit. As mentioned above, Change to a Flat Rest Insert for the Magnetic Base to keep the material flat and stable. Also, a shorter peck drilling cycle will help remove debris and cut more space around the core to minimize binding.

Key Takeaways

We use peck drilling on all our Gunther Drilling Systems for any material type that we are drilling. As we have mentioned above, you will develop your technique that is specific to the material you are drilling, hole position, and how you are drilling it. We hope our experience will help you to learn technique faster so you can maximize the potential of the Gunther Diamond Drilling system.

Whether you're drilling stone, glass, or ceramic, mastering these techniques ensures the longevity of your drill bits and the impeccable finish of your workpieces.

For more information on drilling techniques, check out How to Drill Glass, Stone, and Ceramic.